Key Takeaways

In this article, you will know more about tooling and fixture design. You will also know more about BMC tooling, drilling fixtures, and machine tooling.

Introduction

As the manufacturing sector continues to advance, tool and fixture design has certainly been invaluable to companies. These help streamline the production processes with efficient methods for holding workpieces. Moreover, investing in innovative tooling and fixture design paves the way for adopting various techniques that are transforming the ways in which products are manufactured.

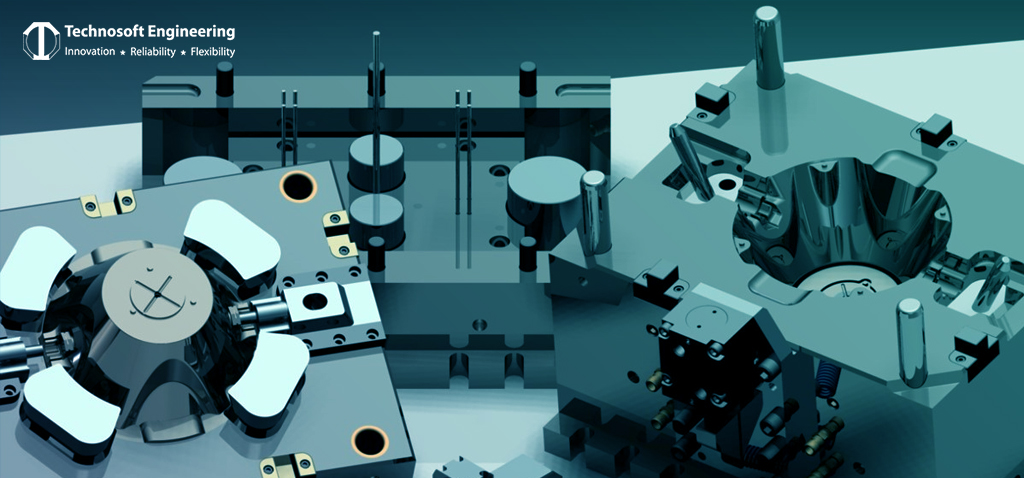

Tooling and Fixture Design Overview

Tools and fixture design is the process of developing certain kinds of equipment and devices that help manufacture many components.

While experts create tools like jigs, molds, and dies along with cutting tools, they consider many aspects. These include heat treatment, geometry, material selection, and surface finish. As a result, the design team ensures that the tool lasts for a long time and performs well during several operations.

Fixtures are devices that hold workpieces securely during inspections or machine assemblies. Such devices offer stability and accuracy, which are vital for maintaining quality in the production phase. But, unlike tooling, fixture design involves determining suitable clamping mechanisms, supporting features, and introducing features that can help professionals load and unload parts with ease.

What is a Tooling Fixture in Manufacturing?

In many industries, a product is made using several components and procedures in manufacturing. In such a case, tooling fixtures support or position a workpiece during machining, testing, or inspection. Most of the time, such fixtures are designed as per the requirements of the manufacturing process. These are also custom-designed to secure workpieces properly. Let’s look at the purposes of tooling fixtures.

Workpiece Stability

Tooling fixtures stabilize workpieces during assembly or machining. This device prevents the movement of workpieces that could otherwise lead to errors or inaccuracies.

Accuracy and Precision

While fixtures help in positioning workpieces, they also ensure that the machining process is carried out accurately as per the required specifications.

Repeatability

By securely holding workpieces in a certain position, fixtures support the repeatability of manufacturing processes. This allows for the maintenance of consistent quality and precision in dimensions, especially when a large number of products are manufactured.

Safety

As fixtures are often used by workers, they mitigate the occurrence of accidents even when individuals are handling heavy workpieces during the entire machining process.

The Different Components Of Tooling Fixtures.

Base plate or Base Body

This component is made from cast iron or steel, and it serves as a foundation for the fixture. As it usually rests on the workbench, it offers stability and support.

Clamping Mechanism

Such mechanisms are used to secure workpieces in the required position. These include screws, clamps, vises, or other fastening devices.

Holding Elements

These components come into direct contact with workpieces. Due to their specialized shapes, such elements ensure proper grip and prevent the likelihood of damage to workpieces.

Guide Elements

Such types of elements ensure the positioning and alignment of workpieces. The elements may include bushings, pins, slots, or other elements that can keep workpieces in a suitable orientation.

Eventually, operators may use additional support elements, like support blocks or risers, to prevent vibration during machining. In some cases, fixtures may also have modular components that can be reorganized to keep different workpieces stable. This enhances flexibility and versatility in various processes.

So, when you’re busy machining intricate components or assembling a complicated product, a properly designed fixture can help achieve optimal results.

Bulk Molding Compound (BMC) Tooling

Bulk Molding Compound (BMC) Tooling is nothing but the process and essential tools that are used in manufacturing components through BMC material. The compound that workers used in the process comprise thermosetting resins, fillers, glass fibers, and catalysts. These ingredients are thoroughly mixed together to form a dough-like material that can be molded under intense pressure and heat. However, the quality of every ingredient varies depending on the application.

Let’s know more about BMC tooling.

Compression Molding Process

During this process, the BMC material is placed in a hot mold cavity. Soon after placing the material, the mold is closed, and it’s subjected to high pressure to compress the compound. Due to intense heat and pressure, the material becomes hard and takes the form of the desired component. To reduce the intensity of heat generated during hardening, workers integrate cooling systems like heat exchangers or water channels. These help to control the temperature and expedite the cooling of the molded components.

Tooling Design

BMC tooling usually involves the design and creation of tooling dies that define the overall shape of the final BMC components. While such molds are made from aluminum or steel, they are led through a machining process. This helps to produce dies with precision and with the desired specifications. Apart from having complex geometries, the mold cavity has bosses, ribs, undercuts, and numerous other features.

Mold Release Agents

Once BMC parts are formed, mold release agents are applied to the mold’s surface. These agents not only prevent the material from sticking but also support smooth ejection of the final parts.

Towards the end, the BMC parts may undergo finishing once they are removed from the mold. Such an operation helps in removing excess material and making rough edges smooth. The process may also involve surface treatment only if it’s required.

Owing to its dimensional stability, corrosion resistance, and design flexibility, the BMC tool is widely used in different industries. As workers use BMC tooling, they can produce automotive parts, electrical housings, and parts for various appliances.

Drilling Fixtures and Tooling

When workers use specialized equipment to drill holes accurately in workpieces, these are known as drilling fixtures and tooling. As the fixtures and tooling play their role in holding workpieces firmly, they direct the drilling tool to a certain orientation. Before the worker starts drilling, they use bolts, screws, vises, and more to keep the workpiece stationary and stable. But, to ensure that the drilling tool is in its position and is aligned with the workpiece, workers may use tool holders. As they continue drilling the workpiece, they also use coolants to improve the surface finish and reduce heat generation.

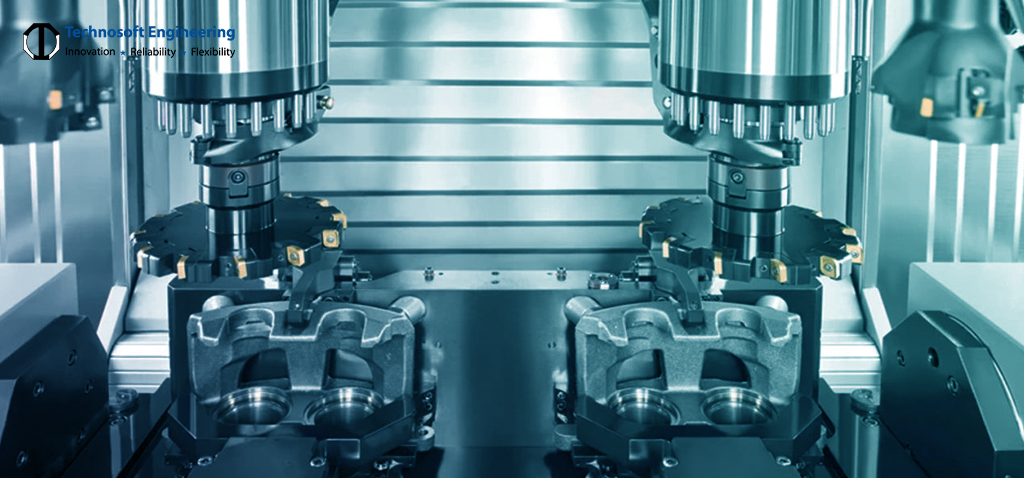

Machine Tool & Fixtures

The process of designing, fabricating, and using certain tools and fixtures in different machine operations is known as machine tooling. Once workers start using the tools, they can use them with machine tools, like power-driven machines. As a result, the machine and the tools enable workers to shape the metal into the desired form. Beyond this, accessories like tool changers, tool setters, chip conveyors, and probing systems are also included in machine tooling. Fixtures and jigs, on the other hand, are further used to hold workpieces in place during machining operations.

Partner with Technosoft Engineering

At Technosoft, you can always expect unmatched accuracy with tool and fixture designs. While we understand your requirements, we offer customized solutions to address those needs. Our team of skilled engineers is always dedicated to assuring excellence and ensuring that fixtures or tools are designed to the highest quality standards. Experts at Technosoft Engineering also optimize designs for enhanced productivity at the factory.

Closing Thoughts

Finally, organizations will continue to rely on fixture design and tooling because the teams have to accommodate a wide range of production volumes. Meticulously designed fixtures will also help to enhance manufacturing efficiency and optimize the use of materials. As organizations try to conserve resources, the designs will also optimize waste generation and energy consumption across the production unit.