Revolutionizing Industries through Smart Precision in the Digital Manufacturing Frontier with Technosoft Engineering

Technosoft Engineering, where we redefine the landscape of manufacturing through our well-defined solutions in digital and smart manufacturing. As pioneers in industrial innovation, we integrate digital technologies to elevate manufacturing processes, ensuring efficiency, flexibility, and innovation. Our expertise spans the realms of digital manufacturing, leveraging tools like computer-aided design (CAD), computer-aided manufacturing (CAM), and simulations for comprehensive digital prototyping.

Going beyond, our smart manufacturing initiatives harness the power of the Internet of Things (IoT), big data analytics, digital twin, SCADA / MES, machine health & maintenance, and cyber-physical systems to create an intelligent, connected manufacturing environment. At Technosoft Engineering, we are not just part of Industry 4.0 we drive it forward, delivering solutions that optimize the entire manufacturing ecosystem.

Our Offerings

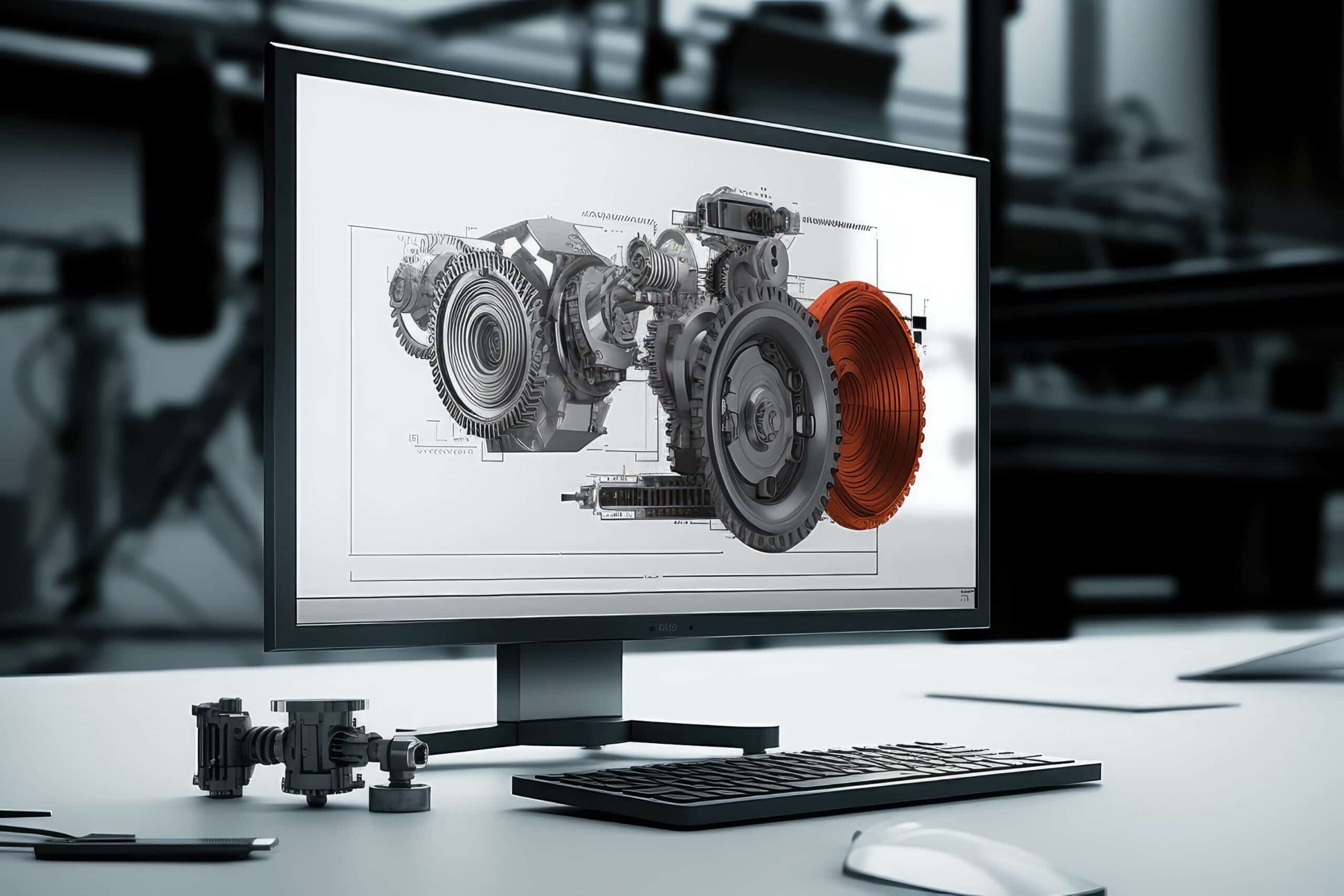

Computer-Aided Manufacturing

Technosoft Engineering offers advanced Computer-Aided Manufacturing that controls machine tools and optimizes manufacturing processes.

Machine Health & Maintenance Solutions

Technosoft specializes in implementation of Artificial Intelligence and IoT technology for predictive asset maintenance and condition monitoring.

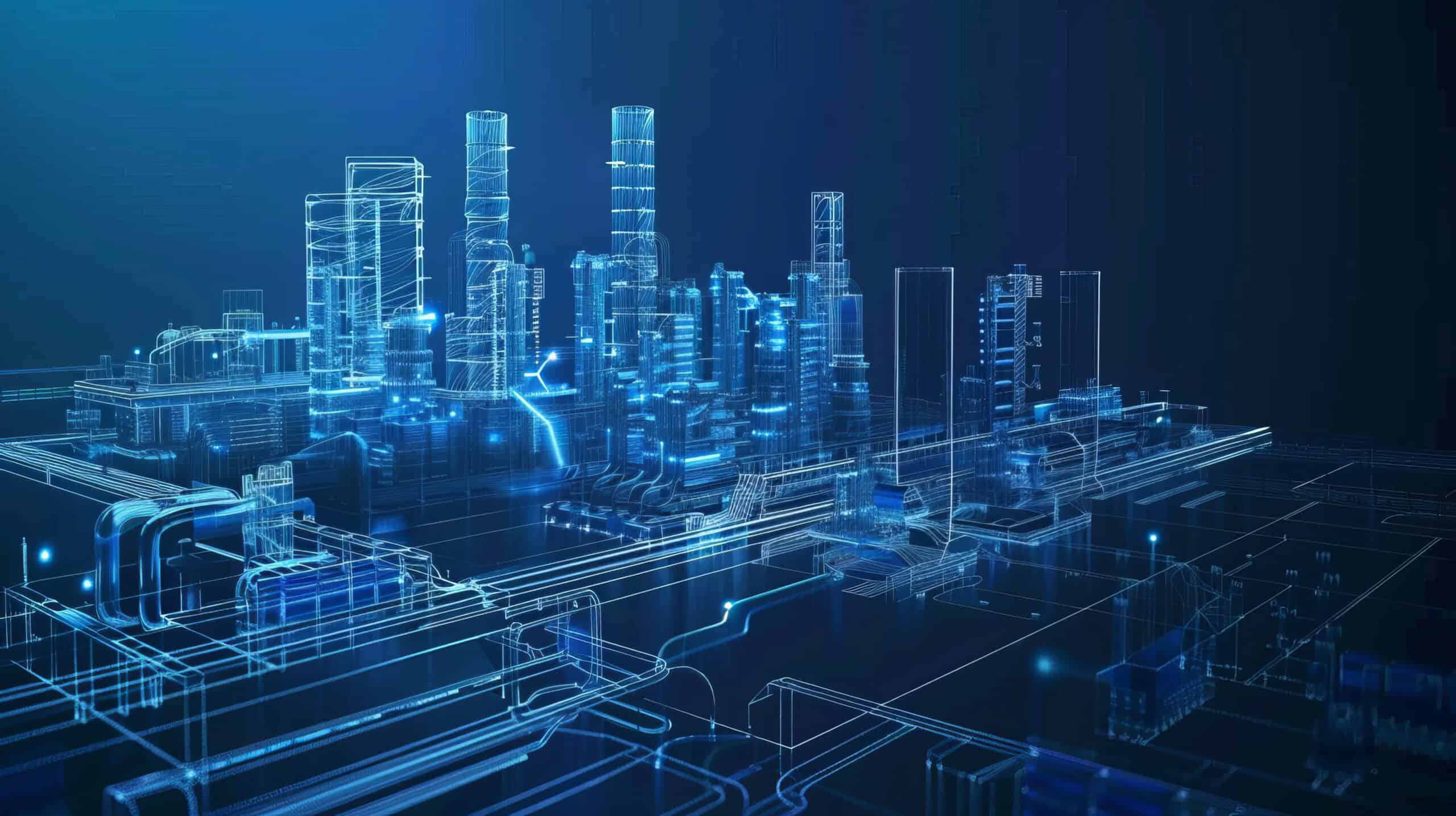

Plant Simulation & Digital Factory Solutions

Technosoft provides plant simulation and digital factory solutions that include virtual prototyping, performance monitoring, process optimization, and real-time data integration

Industry 4.0 Assessment

Technosoft Engineering identifies current technologies in use and evaluates their alignment with Industry 4.0 standards including IoT devices, sensors, and automation in every engineering solution.

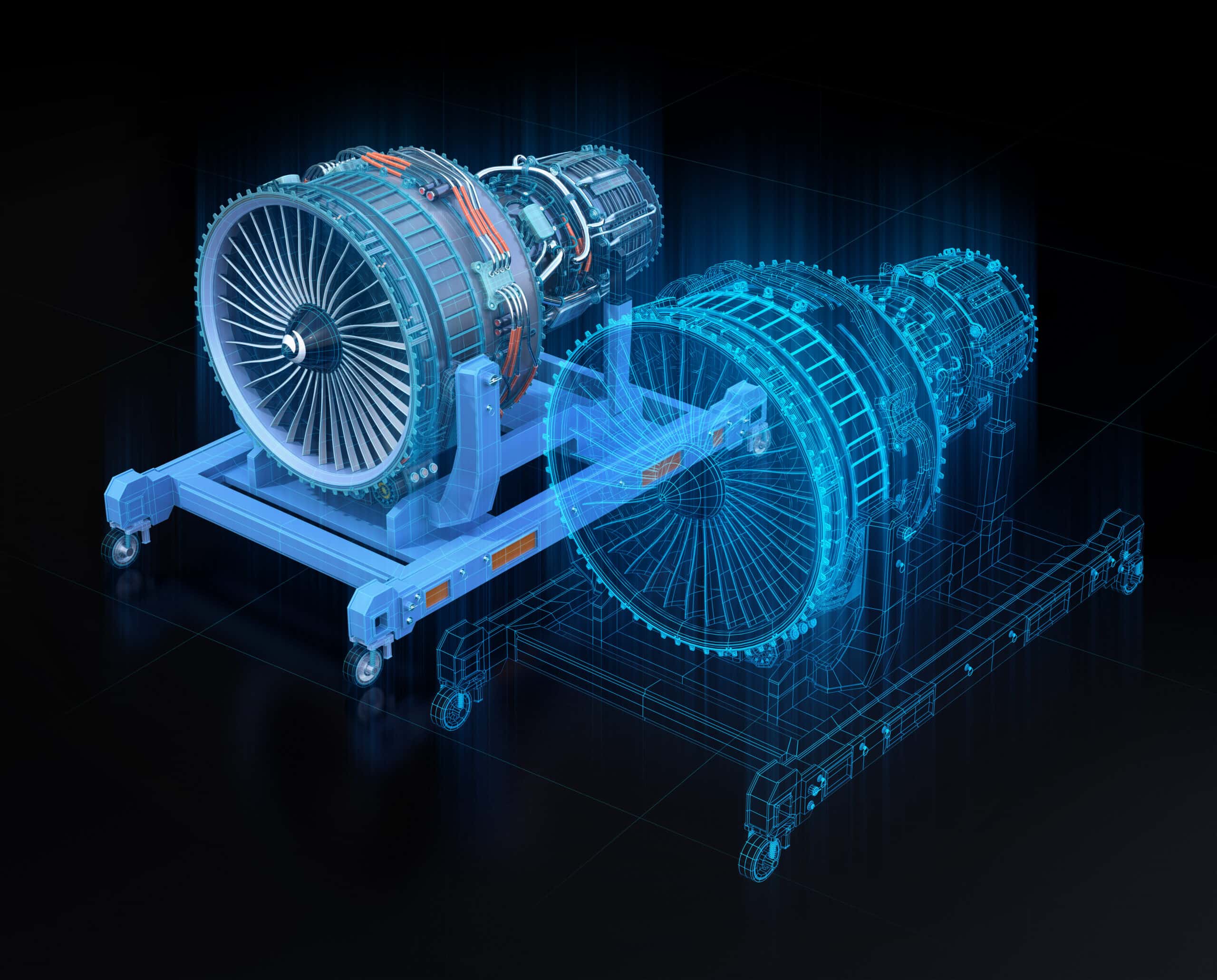

Digital Twin

Our smart manufacturing extends the Digital Twin to represent elements in the supply chain and for virtual quality control simulations which can improve product quality through real-time monitoring and simulation-based quality assurance.

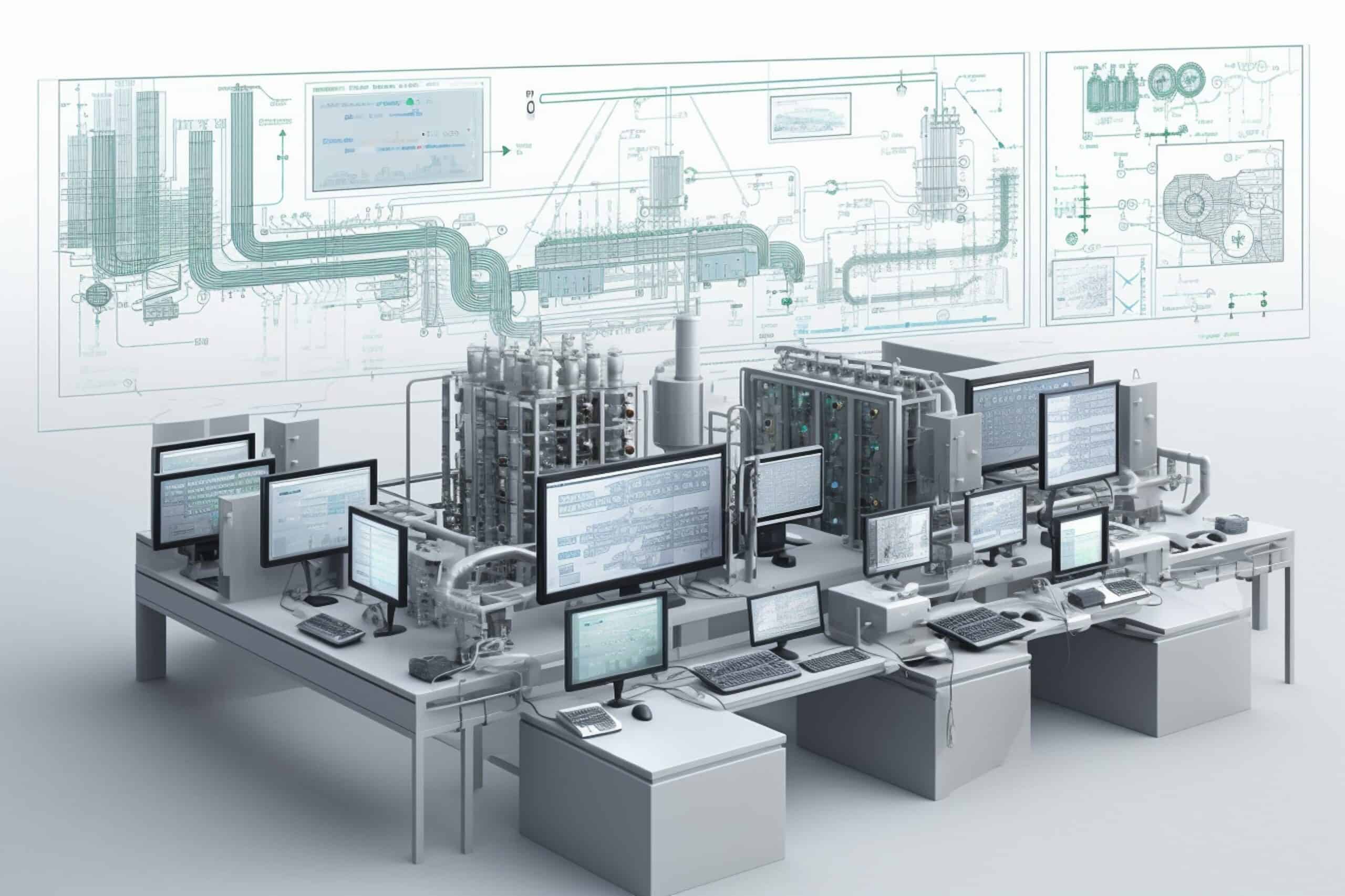

SCADA

Our SCADA (Supervisory Control and Data Acquisition) solutions offer real-time data acquisition, visualization, and control functionalities, enabling operators to monitor the performance of equipment, processes, and assets remotely.

MES

Techonosoft’s Manufacturing Execution System (MES) solution provide comprehensive capabilities for planning, scheduling, tracking, and analyzing manufacturing operations in real time.

Why Choose Technosoft for Smart Manufacturing?

Manufacturing Innovation

At Technosoft Engineering, innovation is not just a buzzword – it’s ingrained in our DNA. We continuously push the boundaries of what’s possible, leveraging our deep understanding of smart manufacturing to bring forth solutions that redefine efficiency, flexibility, and innovation across your entire manufacturing ecosystem.

Tailored Digital Threads

We don’t just offer solutions but also craft a digital thread tailored to the unique needs of your industry. This digital thread seamlessly weaves through your product lifecycle, manufacturing operations, and supply chain, creating an intelligent and adaptive manufacturing environment that propels you into the future.

Local Impact

With a global presence, we combine the excellence of our global team with an understanding of local manufacturing. This dual perspective allows us to offer solutions that are not just globally competitive but also locally relevant and impactful.

Customer-Centric Innovation

Technosoft Engineering places your needs at the center of everything we do. Our customer-centric approach ensures that our solutions are not just technologically advanced but also align with your strategic goals and operational requirements.