In the fast-paced landscape of modern business, the pursuit of efficiency, optimization, and innovation stands as a cornerstone of success. Among the methodologies that empower organizations to achieve these goals, value engineering plans emerges as a powerful strategy. Rooted in the principles of enhancing value while minimizing costs, it’s a methodology that fosters ingenuity and streamlines processes across industries.

Let’s understand more about this.

Understanding Value Engineering

Value Engineering (VE) is a systematic and organized approach used to analyze and improve the value of products, projects, or processes. It aims to maximize the functionality, quality, and performance while minimizing costs. The primary goal of value engineering is to achieve the desired functions at the lowest overall cost without sacrificing quality or performance.

History of Value Engineering

The Origins of Value Engineering

Value engineering, also known as value analysis, is a systematic method of identifying and eliminating unnecessary costs in products and services. It originated in the 1940s at General Electric, during a time of critical shortages of materials and skilled labor due to World War II.

Lawrence Miles, a young purchase engineer at General Electric, was tasked with finding ways to reduce costs without compromising product quality. He realized that many products were unnecessarily expensive because they were designed with materials and components that were more costly than necessary for their function.

Miles developed a systematic approach to identifying and eliminating these unnecessary costs. He called this approach “value analysis.” Value analysis quickly gained popularity at General Electric and was soon adopted by other companies as well.

The Evolution of Value Engineering

In the 1950s, value analysis evolved into a more formal methodology known as “value engineering.” Value engineering is now a widely used practice in many industries, including manufacturing, construction, and healthcare.

The Society of American Value Engineers (SAVE) was founded in 1959 to promote the use of value engineering. SAVE is now known as SAVE International and has members in over 60 countries.

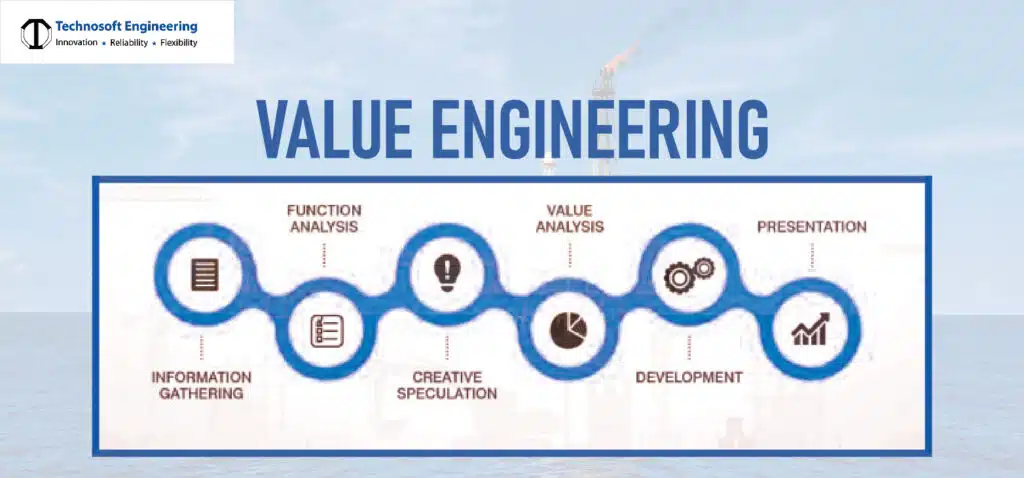

The Five Phases of Value Engineering

Value engineering is a systematic process that is typically divided into five phases:

- Information Gathering: The first phase involves gathering information about the product or service being analyzed. This information may include data on the product’s design, materials, manufacturing processes, and cost.

- Function Analysis: In the second phase, the value engineering team analyzes the functions of the product or service. They ask themselves, “What is the essential function of this component or process?”

- Creative Thinking: The third phase is where the team generates ideas for how to eliminate or reduce the cost of the product or service. They may consider using alternative materials, simplifying designs, or eliminating unnecessary steps in the manufacturing process.

- Evaluation: In the fourth phase, the team evaluates the feasibility and cost savings of each of the ideas they generated. They may also consider the impact of each idea on the product’s quality and performance.

- Implementation: The fifth phase involves implementing the most promising ideas. This may involve redesigning the product, changing the manufacturing process, or training employees on new procedures.

Technosoft Value Engineering Company delivers value engineering solutions that optimize cost, quality, safety, and resource utilization to maximize your product’s value proposition.

Steps in Value Engineering

Here are the steps involved in Value Engineering:

- Preparation and Information Gathering:

- Define the scope and objectives of the project or product.

- Gather relevant information, including specifications, requirements, and constraints.

- Function Analysis:

- Identify the primary functions that the product or project must fulfill. These are the essential purposes or actions it needs to perform.

- Classify functions into primary (essential), secondary (supporting), and unnecessary.

- Creative Idea Generation:

- Brainstorm ideas and alternatives to perform the essential functions.

- Encourage diverse perspectives and creative thinking to generate a wide range of ideas.

- Evaluation and Value Analysis:

- Assess each alternative in terms of its ability to perform the essential functions.

- Consider factors like cost, performance, quality, and feasibility.

- Cost Analysis:

- Evaluate the costs associated with each alternative, including initial costs, operational costs, maintenance costs, etc.

- Identify areas where cost savings or efficiencies can be achieved without compromising essential functions.

- Decision Making for Development:

- Select the most effective and efficient alternative based on the analysis conducted.

- Prioritize solutions that offer the best value by balancing performance, quality, and cost.

- Implementation and Documentation:

- Develop detailed plans for implementing the selected alternatives.

- Document the entire Value Engineering process, including the analysis, decisions made, and reasons behind them.

- Follow-Up and Monitoring:

- Monitor the implementation of the chosen alternatives to ensure they meet the expected outcomes.

- Make any necessary adjustments or improvements based on feedback and performance.

These steps are iterative and may involve revisiting previous stages to refine solutions or explore new alternatives. The goal of Value Engineering is to optimize value by maximizing performance while minimizing costs or resources required.

Benefits of Value Engineering

Here are detailed benefits of employing value engineering:

- Cost Savings: VE aims to achieve cost reductions without compromising quality or performance. By identifying unnecessary elements or finding more cost-effective alternatives, it can significantly reduce production, operational, or lifecycle costs.

- Improved Efficiency: Through the examination of processes and resources, VE can streamline operations, eliminate waste, and enhance overall efficiency. This often leads to quicker production cycles and more efficient use of resources.

- Enhanced Quality: VE doesn’t just focus on cost-cutting; it aims to optimize performance and quality. By identifying better materials or methods, it can enhance the quality and durability of the end product or service.

- Innovation and Creativity: VE encourages creative thinking and innovation. It prompts teams to think outside the box, fostering innovative solutions that can improve existing designs or processes.

- Risk Mitigation: By analyzing various options and potential risks, VE helps in identifying and mitigating potential problems or failure points in a project. This proactive approach reduces the likelihood of unexpected issues arising later on.

- Customer Satisfaction: Improved quality and performance resulting from value engineering can lead to higher customer satisfaction. Meeting or exceeding customer expectations often leads to increased loyalty and positive word-of-mouth.

- Environmental Benefits: VE can promote environmentally friendly practices by optimizing resource use, reducing waste, and selecting materials or methods that have a lower environmental impact.

- Competitive Advantage: Companies that consistently apply value engineering techniques often gain a competitive edge. By offering better quality at a lower cost or by introducing innovative products or services, they stand out in the market.

- Cross-Functional Collaboration: VE involves various stakeholders working together, including engineers, designers, suppliers, and managers. This collaborative approach fosters teamwork and a deeper understanding of different perspectives, leading to better solutions.

- Continuous Improvement: VE is not a one-time event but a continuous process. It encourages ongoing assessment and improvement, fostering a culture of continuous improvement within an organization.

- Time Savings: Through streamlining processes and eliminating inefficiencies, VE can often lead to time savings in production, development, or delivery, allowing products or services to reach the market more quickly.

- Return on Investment: While there might be initial costs associated with implementing VE, the long-term benefits often outweigh these costs. Higher returns on investment can be achieved through reduced expenses, increased sales, or improved customer satisfaction.

In summary, value engineering is a multifaceted approach that goes beyond cost-cutting, aiming to optimize value by improving quality, efficiency, innovation, and customer satisfaction while minimizing risks and environmental impact.

Conclusion

Technosoft comprehensive value engineering services encompass product design optimization, material selection, manufacturing process improvement, and supply chain optimization, enabling you to maximize the value proposition of your products while minimizing costs and enhancing overall performance.

Comments are closed