What is Embedded System – 2023 Future Aspect.

Leave a CommentAutomation is the latest technology that reduces human intervention in the process by predetermining decision criteria, subprocess relations, and related actions. To automate the processes; mechanical, hydraulic, pneumatic, electrical, electronic, and computer devices are used.

If we look at global statistics, over 67% of companies use automation solutions to improve visibility and productivity. These intricate systems have embedded systems that are based on microcontrollers (i.e., microprocessors with integrated memory and peripheral interfaces), that are dedicated to specific tasks. These systems can be optimized to increase their reliability and performance.

The merger of technologies (i.e., automation+embedded systems) is opening doors that assist in tasks by improving quality, accuracy, precision, cost reduction, and savings.

This blog is a detailed overview of how important embedded systems are in an automation process.

What are embedded systems?

An embedded system is a computer system (composed of a computer processor, computer memory, and input/output peripheral devices) that serves a specific purpose within a larger mechanical or electronic system.

It is an integral component of a complete device, which typically includes electrical or electronic hardware and mechanical components. Because an embedded system typically controls the physical operations of the machine in which it is embedded, it is frequently constrained by real-time computing requirements.

How does an embedded system work?

Embedded systems’ design resembles miniaturized circuit boards with a processor, power supply, memory, and communication ports for communicating with other components of a larger system. It is possible for the processor to be a microprocessor or microcontroller.

Systems on Chips (SoCs), which include multiple processors and interfaces on a single chip, are one of the most prevalent trends in embedded system technology. They are frequently employed in high-volume embedded systems.

In the industrial IoT (IIoT) ecosystem, SoC has facilitated the development of new design methodologies, products, and solutions. Real-time operating environments are frequently suitable for SoC-embedded technology that is typically fast enough and tolerant of slight variations in response time.

Which are the most recent embedded system architectures?

The most commonly used embedded system design architectures are-

- Simple control loop

It is software that consists of a simple monitoring loop for input devices. The loop invokes subroutines, each of which manages a distinct hardware or software component. It is therefore referred to as a simple control loop or programmed input-output.

- Cooperative multitasking

In this, the loop is hidden in an API. The programmer defines a series of tasks, and each task receives its own “run” environment. When a task is inactive, it invokes an idle routine, which is typically referred to as “pause,” “wait,” “yield,” “nop” (which stands for no operation), etc.

- Interrupt-controlled system

These embedded systems are primarily governed by interrupts. This means that system tasks are triggered by various types of events; for instance, a timer at a predefined interval or a serial port controller receiving data could generate an interrupt.

- Preemptive multitasking or multi-threading

In this type of system, a low-level piece of code uses a timer to switch between tasks or threads (connected to an interrupt). This is the level at which an “operating system” kernel is generally considered to exist. Depending on the required functionality, it introduces more or less the complexities of conceptually managing multiple tasks running in parallel.

- Microkernels and exokernels

A microkernel is logically superior to a real-time operating system. Typically, the kernel of the operating system allocates memory and switches the CPU between threads of execution. User-mode processes implement fundamental functions such as file systems, network interfaces, and so on.

Which industries use embedded systems for automation?

- Food production:

Each step of the food production process requires the company to monitor product quality, adhere to sanitary regulations, legal, and industry standards, and minimize food waste. Automation and robotics in the industry can assist with these tasks.

For instance, there are artificial intelligence (AI)-powered systems that can distinguish between fresh and rotten fruits, and machine learning (ML) solutions can assist with preventive and predictive equipment maintenance.

- Municipal infrastructure:

Intelligent parking is an illustration of embedded electronics. Powered by sensors, computer vision, and data analysis capabilities, they are quite effective for municipal parking lot management and revenue generation.

- Agriculture:

Water, organic fertilizers, and manual labor are agriculture’s primary drivers. Nonetheless, this procedure can be improved by employing agricultural robots, which are embedded Internet of Things (IoT) systems. They can be used for fertilizing the soil and pulling weeds.

- Manufacturing enterprises:

Embedded systems’ design is central to the development of smart cars. Audi is an example of a car manufacturer that uses embedded systems to track quality and compliance for each component of the assembly line.

- Object trading service:

Large stores and shopping malls can also use an embedded system for controlling and optimizing electricity and heating consumption.

- Pharmaceutical products and medical equipment:

Medical devices are examples of embedded software, but pharmaceutical companies may also use embedded software as part of an industrial control system in the process of medicine production and quality assurance.

What is the future of embedded systems in industrial automation?

Industry 4.0 is bringing us from the first to the fourth generation of the industrial revolution, powered by IoT, data analytics, and AI. Embedded systems only produce raw data. Integrating industry 4.0 technologies creates valuable insights for a robust digital infrastructure, and expands automation and innovation.

Embedded modules are becoming more sophisticated, allowing machines to predict or prescribe solutions that could supplement human decision-making or perform tasks faster than humans. They’re making machines smarter, safer, and more effective, controlling industrial automation. Embedded systems are expected to expand IoT applications like wearables, sensors, drones, video surveillance, 3D printers, and smart transportation.

Need solutions for your automation?

Technosoft Engineering is a one-stop solution for you. We merge technologies like IoT, embedded systems, and hardware systems to deliver a fully-automated system that assists in multiple tasks. We design custom PCBs, hardware components, firmware, electronics, etc., and connect them to networks across the globe to generate expected results.

Besides that, we develop mobility and analytics solutions that unlock backend value and give value-driven output.

So, wait no further and get the best embedded system design solutions with complete automation at Technosoft Engineering.

The Role Of IoT in Industrial Automation

Leave a CommentInternet of Things in industrial automation is a game changer that will reap new benefits. It not only creates scope for innovation, but also helps solve problems at the micro level, enhance operations, and increase productivity. The main aim of industrial automation is to reduce the necessity of people in the manufacturing process and eliminate errors.

IoT in industrial automation can be achieved by mapping industrial processes, understanding micro and macro process, and their relations with machines to automate the process. This entire process involves the interconnection of sensors, instruments, and other devices over a common network to accomplish a task.

Let’s quickly drive through detailed explanations, advantages, and the role of IoT in industrial automation engineering.

What Does IoT Do For Industrial Automation?

IIoT refers to sensors, instruments, and other devices networked with industrial computer applications, such as manufacturing and energy management. This connectivity enables data collection, exchange, and analysis, which may improve productivity and efficiency and have other economic benefits. The IIoT is a Distributed Control System (DCS) evolution that uses cloud computing to refine and optimize process controls.

This is enabled by integrating multiple technologies like cybersecurity, cloud computing, machine-to-machine, 3D printing, advanced robotics, big data, cognitive computing, etc.

Practical Advantages of IoT in Industrial Automation

- Scalability

Scalability in production is attained by increasing output, two goals that the digital industrial transformation facilitates and accelerates. Humans are sometimes the weakest link in production processes, which is unfortunate for the workforce. However, by removing humans from a process and delegating production to robots, businesses are able to increase their throughput.

- System uptime enhancement

Like production, uptime is limited by humans. People need rest, food, a safe workplace, and ethics. Machines don’t need breaks or food. Because of automation, many factory floors are safe.

- Operational efficiency

Operational automation means interconnecting and integrating systems to share information and improve operations exponentially. Computer logic lets systems respond to other needs. This basic application is everywhere now, from turning off lights to alerting global suppliers that a factory will soon run out of raw materials and need resupply.

- High-security access and control

IoT introduces many attack vectors to automation systems, but it also offers a solution. Automation can be used to defend against cyberattacks. It helps defenders make their entire network visible, adhere to a policy-based approach to system configuration, management, and security, and automate many low-level maintenance tasks while alerting IT teams of more serious breaches or attack patterns.

Role of IoT in Industrial Automation

- Internet of Things (IoT)

IoT concepts and technology are being explored and implemented in industrial automation. IoT helps create effective, affordable, and responsive system architectures. The goal is to create frictionless communications and interaction from manufacturing field input/output, including analyzers, actuators, and robotics, to increase flexibility and manufacturing. Industrial automation has used IoT in major applications, such as PLCs replacing banks of relays.

- Internet of Things Products and Devices

Internet-connected IoT devices and systems can collect and exchange data. These products have many forms and use. Some of the examples include:

- Smart thermostats, security cameras, and light bulbs can be controlled remotely via smartphone apps.

- Smartwatches and fitness trackers track a user’s activity and health metrics.

- Connected cars can communicate with each other and with traffic infrastructure using sensors and other technologies.

- Industrial IoT systems can monitor and control factory and warehouse equipment.

IoT products make our lives more convenient and efficient by allowing us to easily collect and access physical data.

- Internet of Things Gateway Devices

IoT gateways connect a network of connected devices to the internet. These devices are used in industrial IoT systems with hundreds or thousands of devices to connect and manage work.

IoT gateways are equipped with hardware and software to perform various tasks. IoT gateway devices have user-friendly interfaces that make configuration and management easy. This can include web-based interfaces, mobile apps, and other tools that make it easy for users to set up and maintain their IoT systems

- Industrial IoT Development Kits

Industrial IoT (IIoT) development kits include hardware and software to help developers create applications and solutions. These kits include sensors, actuators, and other physical components for building and testing IIoT systems, as well as software libraries and other tools for developing and deploying IIoT applications.

IIoT development kits can be customized to meet the needs of a specific industry or application. A manufacturing company’s IIoT development kit may include sensors and other components used in manufacturing, while a transportation company’s kit may include GPS and other location-tracking technologies.

A Quick Recap on Industrial Automation Engineering

The Internet of Things, or IoT, is a network of interconnected, data-collecting and -exchanging devices. By allowing machines to communicate with one another and with central systems, IoT-enabled devices can be used to increase efficiency and productivity in the context of industrial automation.

In industry, for instance, an IoT system could be used to monitor the performance of individual machines and determine when maintenance is required, as well as to automatically adjust production processes based on real-time data. This can help to decrease downtime and increase operational efficiency overall.

Final Thoughts

Want to leverage the best technology for IoT industrial automation? Technosoft Engineering IoT Services will take your Industrial Automation processes to the next level of connectivity and intelligence.

Get in touch with us today for our industrial automation engineering.

What Is Product Design

Leave a CommentProduct design is a set of strategic and tactical activities that cultivates ideas for product commercialization. It combines art, science, and technology to create new products. Product designers conceptualize and evaluate ideas in a systematic manner, transforming them into tangible inventions and products.

The forecasted market of product design and development is expected to be USD 8.21 billion by 2029, with a CAGR of 5.30%. This suggests that the integration of growing technology with product design will boom in the upcoming years. This is also because developing distinctive products significantly to sales revenue.

The objective of product design is to create a product or service with superior functional utility and sales appeal at a reasonable price and in a reasonable amount of time. To understand its importance more precisely, keep reading.

What Is Product Design?

Product design is defined as the process of imagining, creating, and iterating products that solve users’ problems or address specific market needs.

Understanding the end-user, or the individual for whom the product is being created, is essential for successful product design. Product designers use empathy and knowledge of their prospective customers’ habits, behaviors, frustrations, needs, and wants to solve real problems for real people.

Example Of Product Design

When it comes to product design development, designers have numerous options for tools. Before going into production, they can use the conventional method of sketching out concepts on paper and then creating models. Frequently, contemporary designers create 3-D computer models using specialized software that simulates the final appearance of the object.

The best example of product design is Belt Testing Gang Dynamometer Machine, a special-purpose machine made by Technosoft Engineering. The scope of this project was to design a Gand Dynamometer for accelerated failure testing of one-size drive belts. This machine will be able to test 4–8 belts at a time.

The dynamometer integrated mechanical and electrical designs to monitor, record, and notify the belt failure or in case of exceeding a defined percentage of slippage.

What Is The Product Design Process?

There are three basic steps involved in the product design development process.

- Analysis

- Acceptance: Here, the designers commit to the project and find a solution to the issue. They combine their resources to determine the most effective solution to the problem.

- Analysis: In this phase, everyone on the team conducts research. They collect general and specific information that will aid in determining how to solve their problem. This can include, among other things, statistics, questionnaires, and articles.

- Concept: This section defines the central issue of the matter. The problem’s conditions become objectives, and the situation’s constraints become the parameters within which the new design must be developed.

- Synthesis

- Ideate: Here, the designers generate various ideas and solutions for their design problem. The ideal brainstorming session is devoid of bias and judgment, instead focusing on developing original concepts.

- Select: At this point, the designers have narrowed their ideas down to a select few that are guaranteed to be successful, and they can now outline their plan for creating the product.

- Implement: At this stage, prototypes are constructed, the plan outlined in the previous step is realized, and the product begins to take on a physical form.

- Evaluate: In the final phase, the product is evaluated and improvements are made based on the results. Even though this is the final step, the process is not complete. The finished prototype may not function as expected, so it is necessary to generate new ideas.

Why Is The Product Design Important?

Product design is not limited to the product’s aesthetics; it also defines how the product functions.

- If your product design is superior to that of the competitor, it will be chosen over the competition on the market.

- Product design is essential because it provides the consumer with an original and imaginative experience. As a result, the design of the product can attract new customers and foster brand loyalty. The design of a product can go a long way toward creating a memorable experience, which in turn fosters brand loyalty.

- Design is crucial in heavy machinery and services because it can be the difference between efficiency and chaos.

- Product design is a crucial component of the product development procedure. It ensures that the final product is customer-friendly, aesthetically pleasing, and profitable to produce.

- Design can take many forms, and the greater the acceptability of the product’s design over time, the stronger the organization’s brand will be.

- Packaging plays a significant role in product design because it is the final point of influence and, therefore, the company’s final sales point. Good packaging integrated into the design of a product can make a substantial difference.

Get GenX Product Design Development Solutions Here

As mentioned above, product design is the USP of a business, and it needs to be uniquely perfect. So to meet that need, Technosoft Engineering gets you the best solutions. Our process starts from idea generation to execution. We aim to reduce the cycle time and increase the scope and functionality of the product.

Our product design services include market research, product styling, DFA, DMF, reverse engineering, prototyping, material selection, engineering change management, and product costing. You get a solution bundle in one place.So, wait no further and get feature-rich unique product design solutions.

8 Benefits Of Outsourcing Engineering Services

Leave a CommentEngineering organizations are considering outsourcing as the mainstream for top-quality services and long-term strategies. This implies that outsourcing engineering services are becoming an integral part of the organization’s product development process.

The global product engineering services market size is expected to reach 2041.4 billion by 2028, with stable growth of 8.5% CAGR each year. Interpreting, outsourcing is more popular than ever as businesses get ample advantages from streamlining business processes to reducing capital and overhead costs.

This article shall elaborate on why outsourcing engineering services are a must to consider.

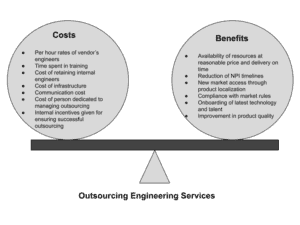

Before analyzing what to outsource, companies must understand product development outsourcing. Cost savings, labor arbitrage, and innovation-led SLAs are all reasons for outsourcing.

It’s important to understand what constitutes a benefit and what directly and indirectly influences the cost of outsourcing engineering services to ensure that benefits outweigh costs.

Before analyzing what to outsource, companies must understand product development outsourcing. Cost savings, labor arbitrage, and innovation-led SLAs are all reasons for outsourcing.

It’s important to understand what constitutes a benefit and what directly and indirectly influences the cost of outsourcing engineering services to ensure that benefits outweigh costs.

If Value = Benefit – Cost, is positive, outsourcing is the best option.

Benefits Of Outsourcing Engineering Services

In 2021, the global engineering services outsourcing market was worth USD 1.3 trillion. From 2022 to 2030, its CAGR is expected to be 24.6%. Engineering Service Providers (ESP) and Original Equipment Manufacturer (OEM) alliances are expected to grow as Engineering Services Outsourcing (ESO) becomes more popular. This popularity is due to the reasons mentioned below.

- Reduction in overhead costs

According to research, outsourcing engineering services can help engineering companies reduce labor costs by 20%–30% while simultaneously reducing revenue spent on other engineering-related services. The revenue saved through outsourcing can be invested in product development, marketing, or other crucial business operations.

- Access to sophisticated engineering services

Customers today demand complex engineering services that may exceed the capabilities of a company with limited in-house executives. However, this issue is easily solvable through engineering outsourcing. Through outsourcing, engineering companies are able to meet the needs of their clients, whether they require advanced 3D animation or intricate geometry.

- Greater focus on core business

When IT isn’t a core business, opting for an engineering service provider is the best choice. This saves time and distractions spared on resources to set up IT, maintenance, and its upgradation.

Additionally, when engineering services are outsourced, a business is able to devote more hours to marketing initiatives. You will be able to devote your time to enhancing your designs and developing more efficient methods. In turn, this will assist you in promoting and marketing your business in new markets.

- Quicker turnaround time

Outsourced engineering services providers work around the clock to measure and accomplish the project, and hence, the turnaround time is faster. They are able to meet the demand for a quick turnaround time more effectively than an in-house team.

In addition, due to the caliber of the provider’s personnel and technology, things are not “rushed through” in a manner that compromises the final product.

- Access to the latest technology

Reputable outsourced engineering services providers typically subscribe to the most recent frameworks and development tools and have access to specialized technologies that they employ on all of their projects. Therefore, you can claim to use cutting-edge technology for your projects without the nightmare expenses and hassles of actually implementing it.

Additionally, you get trained professionals with technological expertise. This will help you leverage high-end technology and software without having to make additional investments.

- Increased customer satisfaction

Customers always have high expectations for precision and speed. However, outsourcing allows you to easily meet both of these requirements. A customer who is satisfied is more likely to request your services in the future. The best way to maintain a consistent level of customer satisfaction is to select a service provider who is both experienced and focused.

- Using as-per-need services

The need for engineering services is not constant. In that case, even when there is a lull in the engineering industry, companies must pay full-time wages to their employees. It is not comparable to outsourcing. Outsourcing engineering services provides greater flexibility because engineering firms will only pay for the services they require when they require them.

- Improves risk management

Working with experts not only reduces the number of bugs but also reduces the risk of product failure by ensuring expert assistance is available during times of crisis. Moreover, if you are launching a new product or offering a new service, an offshore team can be quickly adjusted to meet soaring demand, as compared to a team from a developed nation.

Engineering Services At Technosoft

Outsourcing engineering services has added advantages, including a reduction in overhead costs, access to sophisticated engineering services, a quick turnaround time, a greater focus on core business, improved risk management, and much more.

Technosoft is the leading engineering services provider, with a team of over 400 engineers and designers. Technosoft is able to provide multidisciplinary engineering services in its five business lines—engineering, consulting, innovation, resources, and content—due to the flexibility and breadth of its resources.

So wait no further and book your consultation call today!

IoT In Manufacturing: 2023 Edition

Leave a CommentThe research suggests that the global IoT in the manufacturing market was valued at USD 205.8 billion in 2021 and is expected to touch USD 1.53 trillion by 2030, with a CGAR of 24.91% between 2022 and 2030.

These statistics proclaim that the path of digital transformation in manufacturing is through IoT manufacturing. This sector uses a network of sensors to gather production data and uses cloud software to transform that data into insightful knowledge. Today, industrial IoT solutions are the core driving force behind Industry 4.0.

This article will discuss the role of IoT in manufacturing.

What is the industrial internet of things (IIoT)?

IIoT refers to interconnected sensors, instruments, and other devices networked together with computers’ industrial applications. These applications include manufacturing and energy management. IoT device connectivity enables the collection, exchange, and analysis of data, which may facilitate productivity and efficiency improvements as well as other economic benefits.

The main motive of industrial IoT solutions is to improve efficiency in manufacturing, supply chain, and management contexts.

The architecture of IoT in manufacturing

Traditionally, IIoT systems are developed as digital technology with a modular layered architecture.

| Contact Layer | User interface devices like computer screens, PoS stations, smart glasses, touch surfaces, tablets, buttons, etc. |

| Service Layer | Software to analyze data and transform it into actionable data, which is displayed on the driver’s dashboard. |

| Network Layer | Wi-Fi, Bluetooth, LoRa, communication protocols, cellular, cloud computing |

| Device Layer | Hardware components like sensors, machines, CPS, etc |

Impact of Industrial Internet of Things in three verticals

- Shop floor and field operations

Embedded sensors in machinery and equipment collect real-time data on operational conditions and the condition of spare parts. The provided data is subsequently analyzed by the cloud platform. The results are then shown in a user application, providing shop floor supervisors with a comprehensive perspective of the production process.

Its applications can be divided into two groups:

- Supporting manufacturing operations: This involves monitoring of equipment utilization, product quality control based on condition, and safety.

- Facilitating industrial asset management: This involves industrial asset tracking, inventory management, and predictive maintenance (based on condition monitoring).

- The manufacturing supply chain

IoT devices ensure end-to-end supply chain management. Manufacturers can, for example, monitor the movement of vehicles delivering supplies and commodities, view extensive information on things in warehouses, and manage the conditions (temperature, humidity) under which products are stored or moved.

- Remote and outsourced operations

Typically, modern businesses are not located in a particular region; rather, they have several affiliates and branches dispersed across the globe. Moreover, they can outsource their manufacturing processes to third-party manufacturers in order to save money on shipping or infrastructure.

IoT solutions and services provide centralized monitoring of all decentralized and outsourced processes. This is the most effective method for guaranteeing that all contractors adhere to the technological process and that all manufactured goods meet predetermined requirements.

Applications of IoT in manufacturing

- Smart packaging

It uses IoT that allows customers to engage and generate data for better product management in the future. IoT and packaging interact through sensors, QR codes, AR, VR, and mixed reality. Smart asset tracking provides consumer value while collecting data and improving operations and efficiency.

- Predictive maintenance

Embedded IoT devices in machines can detect temperature, pressure, voltage, etc. malfunctions and warn appropriate staff, leaving employees to take remedial action. Predictive maintenance helps technical support staff find and fix defects before they cause catastrophic equipment failure, lowering downtime and costs.

IoT-connected equipment can be combined with advanced analytics tools for predictive maintenance.

- Remote production control

IoT in manufacturing allows remote process monitoring and equipment configuration. First, workers can remotely collect data on industrial processes to verify if they comply with norms and requirements.

Second, they may remotely configure equipment, saving time and effort. Businesses can use IoT software development services to simplify equipment administration and control via virtual networks.

- Asset management

Manufacturers can collect and monitor real-time asset data via the web or mobile apps. IIoT devices provide industrial asset tracking by doing the following.

- Goods-carrying vehicle

- Inventory

- Resource-related production

With the industrial internet of things, you can track and optimize assets from the supply chain to the finished product.

Asset monitoring detects problems that affect product quality or time-to-market early and accurately.

- Digital twins

These include IoT, AI, ML, and cloud computing. Digital twins facilitate the digital transition in production and may be advantageous on the factory floor. Using virtual reproductions of equipment and replacement parts, engineers and management can mimic operations, run tests, detect defects, and achieve desired results without destroying actual assets.

4.0 Industrial IoT solutions trends in 2022

- Sensor advances and innovations

With advances in communications technology, especially the deployment of 5G networking, facilities will be able to install more sensors, collect more data, and act on more information. Multiple sensors give a high-end view of operations and more insight into unforeseen events—and the potential to prevent them.

- Analyzing data at source

With vast amounts of data being continuously collected and analyzed, some smart factories are modifying their technical architecture by bringing data analysis and artificial intelligence (AI) technology to the “edge” — the point of data collection — to drive technical decision-making and analytics without the need for a massive, overloaded central repository, which can slow down analysis and action.

Final Word

With a bag of applications, IoT in manufacturing also comes with benefits like cost-efficiency, improved decision-making, quicker time-to-market, improved safety, high customer satisfaction, and much more. Businesses can adopt this technology to maximize productivity by ensuring production uptime, lowering expenses, and eliminating waste.

Technosoft Engineering specializes in advanced embedded systems, IoT solutions, IIoT solutions, automation, sensor technology, and much more. Our aim is to leverage IoT data to increase demand forecasting and boost supply chain operations. Though complex in nature, we try to simplify every solution and augment your output.

Engineering Design Process – Technosoft Engineering

Leave a CommentEngineering design is the creation of systems curated with human effort. It is the result of integrating multiple technologies to solve a problem or meet user needs. The engineering design process involves step-by-step methodology from describing the problem statement to providing its solution.

Solving design problems is an iterative process as the solution to the design problem evolves and requires continuous refinement. It is a decision-making process that applies basic sciences, mathematics, and engineering science to meet the stated objective. The key elements of the engineering design process are the establishment of objectives and criteria; synthesis; analysis; prototyping; testing; and post-analysis.

This blog specifically targets elaboration at every stage of the design process.

Stages Of Engineering Design Process

- Defining problem

The design process starts with asking questions about the observed problems.

- What is the need for design?

- Who has this problem?

- Why is it important to solve?

- How will the design address the pain point?

- What resources are needed to curate the solution?

- How is the solution better than other solutions in the market?

This set of the right questions helps to justify the design solution in the first place.

- Research

This includes interacting with individuals from a variety of backgrounds and expertise to assist in determining what products or solutions already exist or what technologies could be adapted to meet end needs. In the existing relevant literature, problems and successes associated with existing solutions, costs, and market demands should be considered.

Here are some questions to consider.

- Is the problem real and the statement accurate?

- Is there a need for a solution?

- What are the existing solutions to the problem?

- What is the right way of solving the problem?

- What are the economic factors revolving around the solution?

- What are the important factors (e.g., safety, aesthetics, effect on the environment, etc.) to the solution?

The information source should be pertinent. If alternative solutions are commercially available, reverse engineering can be a useful technique. The Internet, local libraries, available government documents, personal organizations, trade journals, vendor catalogs, and available experts are additional sources of information.

- Design requirements

It is also termed “problem definition,” which includes establishing design requirements and analysis of the same. Throughout the engineering design process, the product or process being developed is designed in accordance with the design requirements.

These include functions, attributes, and specifications, which are determined by analyzing user requirements. Hardware and software parameters, maintainability, availability, and testability are some of the design requirements.

- Feasibility

A feasibility study is an evaluation and analysis of a proposed project’s potential to support the decision-making process. It outlines and evaluates potential alternatives or methods for attaining the desired result. The feasibility study narrows the project’s scope in order to identify the optimal scenario.

The objective of feasibility analysis is to determine if the engineer’s project can proceed to the design phase. This is based on two criteria: the project must be based on a feasible concept, and it must be feasible financially.

- Conceptualization

Here, the pros and cons of the proposed idea are weighed. This stage is important because it mitigates the risk of errors, odds, manages costs, assesses risk, and also evaluates the potential success of the project. It is always suggested to propose multiple solutions, and potential solutions must be identified.

The noted ones are different ways to approach different solutions.

- Morphological analysis: In a chart, independent design characteristics are listed, and various engineering solutions are proposed for each solution. Typically, a preliminary sketch and brief report are presented alongside the morphological chart.

- Brainstorming: This popular technique entails generating multiple ideas, typically in a small group, and adopting them in some form as a solution to a problem.

- Preliminary design

This stage bridges the gap between design conceptualization and detailed design. In this, the general project location and design concepts are determined. It involves preliminary engineering and analysis activities like-

- Environmental assessments

- Topographic surveys

- Meters and bonds surveys

- Geotechnical investigations

- Hydrologic analysis

- Hydraulic analysis

- Utility engineering

- Revenue estimations, etc.

Subsequently, the overall system configuration is defined in this task, and schematics, diagrams, and layouts of the project may provide early configuration information.

- Detailed design

This procedure entails conceptual design, embodiment design, and detail design, which, when executed professionally, results in a solution that is well-designed. This further involves the following stages-

- Specifications checking

- Defining subsystems, checking, and assembling parts

- Finalizing individual parts and completing technical calculations

- Conforming every part with standards

- Documentation

CAD programs can be used in a detailed design process that can provide optimization with greater accuracy.

- Building a prototype

A prototype is a functioning model of a solution. Generally, it is made with different materials than the final product and is less polished. Prototypes are crucial to the development of a final solution because they allow the designer to test the solution’s functionality.

- Testing and redesigning

The design process involves numerous redesigns and iterations of the final solution. Before settling on a final design, it is likely that you will test your proposed solution, discover new issues, make modifications, and test new solutions.

Final Thoughts

The engineering design process, when systematically executed, generates better products with the seamless integration of multiple technologies. The whole point behind performing detailed research, analysis, and documentation is to come up with a product that solves the problem and adds further value to existing products in the market.

As the whole process requires expertise, outsourcing engineering design becomes a preferable choice. To add value to that choice, Technosoft Engineering is here to process the design stage. Our expertise is but is not limited to-

- General Arrangements & Layout preparation,

- Intelligent part/sub-assembly/assembly/drawing creation

- Geometric Dimensioning & Tolerance, Tolerance Stack-up

- Hydraulic, Pneumatic Circuits & Piping Drawings

- Machining, Fabrication, Weldment drawings for Manufacturing

- BOM/Part list

- Spare/Operation/Maintenance Manuals

So, wait for no further and contact us today. Let’s invent a revolutionary solution!