Guide of Electronic Product Design – Technosoft

Leave a CommentWith the advent of digital technology, the electronics design industry has taken enormous leaps and has brought a 360 degrees of change in the user experience. The electronics sector has been playing and manipulating with electricity from time immemorial and has invented many complex user devices. The process of electronic development of any electronic device is almost similar to a normal engineering product.

Electronic Product Design services start with ideation and market research. Further, it is followed by securing funding and developing the product’s regulatory plan. The next phase concentrates on product design, verification, and validation which require a lot of expertise among the designers and developers. Finally, the company focuses on marketing and sales to boost the product’s acceptability among its customers. Here’s a step by step guide for the Electronic Product Design of an electronic device.

Ideation

The first step of the design and development of an electronic device is to establish an idea about the concept and application of the electronic product. Developers and designers focus on the user’s needs and brainstorm about the next big thing that they want to have in the customer’s life. Idea generation is a very complex task and could consume a lot of time for establishing an idea of a master product.

Market Research

The probability of getting a wonderful idea is very high but such is not the case for its success. Thorough market research is required before finalizing the product. Many developers produce products that are similar to the already available products in the market. In such a case, it becomes a lost commodity and does not generate enough revenue. Developers should note that their product should either be a novel idea or must substitute the other similar products in the market.

Project Timeline and Costs

The project timeline is an important factor that progresses your project with time. It includes the identification of the scheduled future milestones in the project design and development. Significant time should be given to each phase of the project development and developers should focus on achieving the targets within the pre-identified boundaries.

Project Cost is also a crucial factor while developing an electronic product. Each phase of product development requires a significant amount to deliver a result. Businesses should keep track of their finances and should signal flags when the cost overruns the pre decided budget.

Prototype Creation

One of the significant steps in electronic device design and development is the creation of the product prototype. It is done to identify the problems in the product and thereby improving its features. This is a great way to troubleshoot the hurdles that the developers would attend in the future. Prototype creation offers the visualization of a realistic representation of the final product.

Funding and Recruitment

A large chunk of money is required to deliver a product in the market on a large scale. Businesses always have a seed investment to develop their product but they can always go for angel investors and venture capitalists as per their required needs. Angel investors are the investors who provide capital at the start of business development in exchange for ownership while the venture capitalists provide funds for early-stage and emerging companies and provide their expert knowledge to the management.

Recruitment of expert staff is essential for the scale-up of the venture. Electronic device development is complex work and thorough practical knowledge is a prerequisite for successful device development. Businesses should focus on their human resources and should offer essential research and training to their staff before the actual product design and development.

Regulatory Plan

Every electronic device is different and has a specific regulatory plan. Developers should ensure that they create and circulate the specific guidelines before the design and development of the product. These guidelines should have the entire how-to and procedural step by step guide in the development of the products. It should all the pros and cons of a particular step so that the staff becomes familiar with the implementation procedures.

QMS implementation

Implementation of the electronic quality management system offers an advantage in developing standard products without any errors. It ensures that each product has followed the standard government and industrial guidelines and doesn’t possess any harm to the customer.

Design and Development Planning

This phase is the one where a business idea is transformed into reality. Proper planning is required to document and review the design controls. A checklist should be developed and marked each time while progressing into the next step. It ensures the progress of electronic product development is in order without any back draws. A good plan includes breaking down the timeline and description of the activities along with offering the responsibility to a particular supervisor for each activity.

Design Inputs and Outputs

Design inputs are the basis of an electronic device and the quality of the device is dependent on the quality of the design inputs. Any future problems regarding the quality of the device pins down to the design inputs, therefore designers should focus on the standard and quality of the product design with all pros and cons.

Design outputs are the ingredients for the development of the product. It includes manufacturing instructions, specifications, and drawings of a particular product.

Design Verification and Validation

The main goal of the design verification is to ensure that the design inputs are as per the design outputs. It involves product testing on various software to ensure the material strength, product age, and fatigue level of the product. Design verification offers the physical value of the product and hence is a crucial factor in the product development process.

Design validation ensures that your product is safe for the end-user and has gone through a rigorous process of various testing and guidelines.

Design Reviews and Changes

Constant monitoring and review are necessary to ensure the compliance of all the guidelines during the product development process. Design reviews should be taken from all the multiple sources in terms of design, manufacturing, quality, marketing, and regulatory compliance.

The evaluation of the design review is followed by identifying the genuine problems and approving the changes in the electronic device.

Risk Management

Risk management is defined as the logical development and implementation of a plan to deal with potential; future losses. The goal of risk management in the electronics industry is to manage the losses and protect the value of its products. It ensures the safety of the user during the working of the product and thereby improving the quality of life of end-users.

Risk Planning

Risk planning involves defining and describing the use of the product. It includes the description of risk management activities, roles, and responsibilities of the supervisors. At last, the methods of risk control are defined in order to mitigate future risks.

Build Supply Partnerships

Businesses require partners to extend their products and services to the market. The management should ensure that they choose the right partners to promote their products. The partners could be contract manufacturers, consultants, service providers, or distributors, etc. It is also essential to complete regular audits of the partners to avoid any fraudulent activities. The selection of the partners should be based on the experience and knowledge of the market.

Product Registration

The registration of the product is crucial before bringing the product in the market. The product is registered with various agencies to assure that the product is compliant with all the mandatory guidelines.

Product Launch

The end goal of any business is to sell their product in the market. It requires a concrete marketing plan to promote and sell the product in the market. It requires email marketing, social media posts, and extensive advertisements to assure the acceptability of the product in the market. The management should ensure that the launch of the product should create considerable hype and show among the customers.

Setting up a distribution network

A significant aspect of product delivery is the creation of the distribution network. It assures the ease in product distribution to the customers. It helps in offering marketing support and is useful in organizing events such as conferences and exhibitions.

Post Launch Surveillance

Once the product is available to the customers in the market, the businesses have the responsibility to monitor the performance of their electronic device. Post-market surveillance is essential to check any of the drawbacks or problems that the customers possibly be facing.

Customer Feedback

Customer feedback is an important aspect to progress any business. It helps in improving the delivery of services and products. It can assure the level of customer satisfaction among the customers. Responsiveness to customer feedback ensures that the management values the opinion of the customers and thereby enhancing customer experience. It also ensures faster delivery of the information to the customers and improves customer retention.

The end goal of any electronic device is to provide a next-generation customer experience to its users. The businesses are focusing not only on enhancing customer retention but also on the sustainability of their product by following cyclic practices.

Also Read: How Rapid Prototyping Helps You Design And Develop Products Quickly

Computer Aided Engineering in Product Design – Technosoft

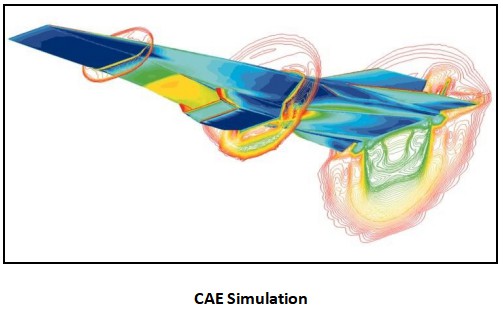

Leave a CommentIn the past, computer aided engineering (CAE) had a very limited application, being primarily used for advanced research and development, and for other specialty tasks which required simulation and optimization. In the modern world, CAE now has a much broader usage, and is routinely used to help accelerate the whole process surrounding product development. In the future, CAE will become even more sophisticated and it will help to model ever more sophisticated designs, while also reducing the time needed for getting a product to market.

Simulating various scenarios has proven to be of enormous value in validating and perfecting the design of various products. One excellent example is how it is no longer necessary to crash a sport utility vehicle into a barrier several times in order to analyze the results. Instead, engineers can conduct virtual crash tests using highly capable computers, and then tweaking designs so as to make the vehicle safer.

It’s not hard to see how a ton of money can be saved by not having to destroy a vehicle in multiple crash tests, and simply simulating the whole process on a high-performance computer. This has significantly increased the value of simulation and moved it solidly toward the direction of the initial phases of design for a product.

It’s very commonplace for engineers to use CAE software for the purpose of creating initial designs, as well as for optimizing the product itself. Some of this optimizing involves subtracting material from a potential product, so as to reduce its overall footprint while making no sacrifices regarding performance or strength. This has allowed CAE engineers to enhance performance as well as ergonomics, increase value and affordability, and to produce products which are more energy- efficient and which are more sustainable.

It’s not an exaggeration to say that simulations such as these have been at the forefront of advancing product development timelines, and that they have created all kinds of innovative designs for improving reliability and quality.

More sophisticated CAE tools

Engineers can also focus on high-value tasks more and more, because software tools have now emerged which automates all the best designs practices, as well as providing sophisticated analysis features. Product engineering has been boosted significantly by using customizable workflow processes that expedite development and testing, as opposed to spending a great deal of time inputting data to a system, and having to validate any particular model. This has freed up time for software engineers, so they can create new designs and develop new capabilities for products which have a ready market.

CAE and Covid-19

With the world currently in the grip of the coronavirus pandemic, CAE has moved to the forefront to provide crucial training for healthcare personnel, so that diagnoses can be quickly formulated, and treatment administered. One of the best examples of how CAE is supporting this effort is with a brand-new Lung Simulator which has been developed to help train clinicians in the techniques which are generally used in lung ultrasounds.

Lung imaging has already been implemented on an international basis to help manage treatment options for those impacted by the Covid-19 virus. Since the CAE lung simulator perfectly replicates many of the properties of actual human tissue, it allows students to practice their ultrasound imaging skills so they can diagnose many of the findings commonly associated with coronavirus.

Using this CAE imaging simulation, students can learn all about ultrasound system controls, applying PPE, recognition and understanding of coronavirus lung anatomy, and the positioning and navigation between intercostal spaces. This is a lifesaving technology which can serve as the best available training tool for identifying coronavirus which has settled into a patient’s lungs. It has been developed so that it perfectly mimics each of the stages of the coronavirus disease as it affects a person’s lungs.

The future of CAE

There are definitely some trends beginning right now in the world of CAE which are expected to intensify in the very near future, and become part of mainstream CAE technology. One of these is the democratization of perpetual licenses which are currently sold by big CAE corporations. There are already a number of CAE applications which are available free of charge or very near free. A whole slew of products is beginning to appear which will allow users to pay as they go, and to use the tools anywhere at all without regard to a specific computing device.

Another trend which is rapidly gaining momentum is that of system modeling with the use of CAE software. Currently, it’s fairly routine for engineers to design and analyze parts or assemblies, but a full system analysis is rarely pursued by designers and developers. Technology which is currently emerging will allow CAE professionals to test entire systems, so that performance of the holistic entity can be analyzed. An example might be the case where several discrete assemblies within an automobile are tested according to current methodologies. In the near future, more testing will focus on analyzing results from a complete automobile, and its behavior under various conditions.

In the past and even in most cases during the present, it has been necessary to perform a new analysis whenever a new design for a product arises. CAE of the future will cut through much of this wasted effort and allow engineers to mine data from other simulations, and couple it with analytics so as to help understand design strengths and weaknesses.

Also see more about: Elements Of CAD Design Services

One really exciting effort which is just beginning to gain traction is known as multi-scale modeling, which offers the opportunity to use the same CAE software to model objects at a molecular level as well as objects the size of a rocket ship. The benefits of having such a capability would be to conduct multi-scale modelling with the same software tool, rather than having to conduct two separate modelling efforts.

It may well be that some of these trends may not receive widespread support in the future, but it does appear that they provide such obvious benefits that it’s very likely most of them will become mainstays of future CAE processes. Look for some or all of these trends to achieve widespread acceptance in the CAE world, and for CAE to become an even more effective tool for designing, developing, and simulating.