Everything About Food Processing Machinery Design? – Technosoft Engineering

Leave a CommentJams and pickles some decades before were homemade. Well, even now they are but not as prevalent as they used to be. Today we get instant food. While Jams and Pickles are basic processed food, nowadays we even get Pasta, Noodles and almost everything packaged. All we have to do is to add some hot water and eat. This is often called as Ready-to-Eat Food. These are processed in a facility and sent worldwide to people of different cultures. Aerated drinks, packaged chips and what not almost everything we see today is processed food.

Engineers who make these huge food processing machines have a lot of creative process going on in their mind. These creative thoughts are triggered by couple of basic principles and understanding of the overall concept. Moreover, they make food processing machinery design with the concept of cooking for the masses. Wish to know how? Then join us in the ride of understanding machinery design.

Understanding Quantity

Now let us connect this with cooking at our home. We all have vessels of different kinds and different sizes. If you’re living alone, you tend to have smaller vessels. If you live with 3 or 4 as a family, you need medium sized vessels and it goes on. In food processing industry, you’re preparing food for masses. It is going to be sent worldwide in packets for sale. Hence every single piece of chips etc. should be perfect and balanced with the right flavours. Vessels play an important role in this matter. You cannot manage to cook for that many with smaller vessels. In manufacturing facility, it is going to be a series of events happening simultaneously. Even if you stop once, you fail to manufacture enough for the rising demand of your product. Hence understanding quantity is the first thing in the mind of design engineers in food processing machinery design.

Using the Right Materials

Again, we use some couple of vessels at home. Some are thick and some are thin. Some are flat and some are hollow. For example, you need thicker pans to make pan cakes as the thinner ones burn them soon. Likewise, if you’re preparing deep fried food items, you need a thin vessel and an option to slow cook or in medium flame. By doing so, you cook fries evenly. Temperature changes from vessel to vessel and even alloy to alloy. If you’re using hard iron base, deep frying might happen with ease. The same you can do with stainless steel, but it might heat up soon.

Cleanliness & Hygiene

When you do something for the masses, you need to keep cleanliness in mind. The vessels are used once and the debris stays. Will you run the machines with the same leftovers? If you say yes, try to say no. This might sound normal in home cooking environment as we don’t use any preservatives. But when it comes to a facility of mass cooking, preservatives are involved and there are chances of insect infestations. But again, it is not that every time you have to clean, once a day will definitely be recommended. Hence a design engineer will always make an option to easy clean the vessel before running it for the next use or the next day. Hence cleanliness & hygiene is an integral part of food processing machinery design.

Technosoft Engineering with an experience of two decades in the field of engineering design offers impeccable solutions to simplify complex processes. Refer to this page to understand how the offerings of Technosoft are unique and how it keeps your ante up in the market.

General Process of Fatigue Analysis

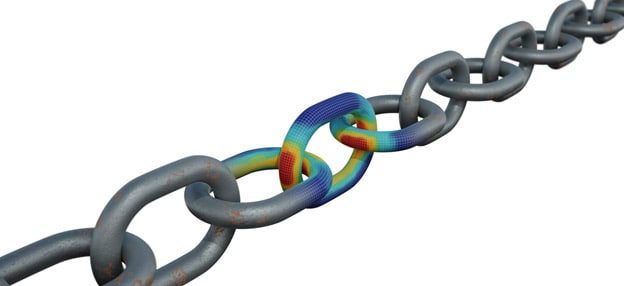

Leave a CommentBefore letting a product in the market, every manufacturer runs a stress test on the product to see if it can withstand in any condition and last for long. So a product should be robust enough and should come through all these tests before entering the market. This is a quality analyzing process. Stress test is still a part of the process; there is a more general term that consumes stress test and i.e. Fatigue Analysis. The name might sound clinical, but its significance is not. Fatigue Analysis is to fundamentally test the capacity of the product and how many life cycles it can take. By doing this, you are releasing a product that is way more viable for your target audience to make you relevant for a prolonged time. Here is the general process involved in Fatigue Analysis.

Time & the No. of Cycles it Should Last

When you make a product you come up with a plan. For example, when you manufacture a battery, you have a time planned for it to last. Your idea will be to let it last for three months. In the contrary, you might even think your product should last forever. But the tiny component comes with limited capacity and every time the one who uses might have to refill the battery. Hence when you manufacture the product, you need to decide how long the product should last.

Stress Analysis for Each Load

When we say each load, it is the cycle it revamps. Let us say the component you manufacture keeps falling down every one year. Hence you have to do a stress analysis for each load i.e. for the each cycle. So you will know how much refill, where to fix, how to fix etc. By doing so, you limit overall damages.

No. of Cycles Each Loading Event in a Cycle Will See

When you reload or refill to revamp the product, you should exactly know the time when the component will fail. So you can approach your clients, get the component and revamp it completely. If you fail to do so, they end up changing it with some other brand. This activity will amp up your relevance in the market.

Find a Fatigue Curve with Correct Loading Ratio to Find Damage Produced by Each Stress Level for Each Loading Event

Times keep changing. We might have a plan, but whatever happens is not going to be as we planned. Hence you should always come with a Plan B to cover up the extra damage. Fatigue Analysis suggests identifying the Fatigue Curve, testing the damage for each stress level and for each loading event. This activity will help you do the right changes while revamping in each and every cycle.

Combine All Damages & Multiply by Desired Safety Factor

Damages in each revamping cycle will differ. Hence you need to keep a note of damages that occurred in every cycle. This will help you ensure that you employ practices to limit the number of damage while manufacturing the next set of components.

Technosoft Engineering with an experience of two decades in the field of engineering design offers impeccable solutions to simplify complex processes. Refer to this page to understand how the offerings of Technosoft are unique and how it keeps your ante up in the market.