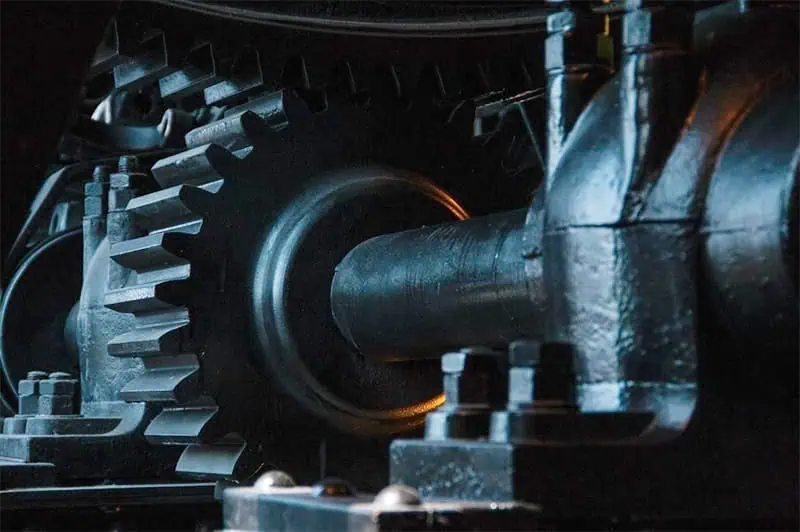

Mechanical engineering design services provide the necessary materials and framework to accomplish the intended functions of the product. Many industrial design firms can design the exterior of a product with an impressive 3D rendering but, while it may not look good, operating requirements are often overlooked. In addition, manufacturers often discard these files, which can cause costly reconstruction and engineering down the road. All of this can be mitigated from the outset, through the use of professional design and incorporation of their equipment building services. Strength is defined by a variety of materials, components, assembly components, etc. Work is available through gears, circuit boards, and other modes performed within the invention. An experienced designer can pinpoint the breakdown points in an industrial design, and plan the necessary internal functionality to ensure the product will last while performing its functions successfully. Therefore, it is effective to combine mechanical and industrial manufacturing at the same time to develop a kind of beauty, durability, and efficiency.

Before producing a machine-made product, it is important to design a similar model and test it. Mechanical engineering services help to process. The designers took the design process in two steps. The conceptual design was originally designed to give a brief overview of the project. After the necessary adjustments or improvements are made, a detailed design is developed that gives a clear idea of what the final product will look like. The CAD drawing is widely accepted in the industry, as they provide a very clear view of the dimensions and views on all sides. In addition, they offer 2D to 3D conversion services and paper and CAD conversion options. Product and engineering analysis of the product is also possible with techniques such as thermal analysis. It refers to the behavioral analysis of a product and its properties in relation to changes in temperature conditions. It is especially important in the case of electronic and automotive heaters. They are especially vulnerable to temperature changes. Mechanical construction services help to address such issues and construction products appropriately. The procedure tests the function of certain body structures, such as enthalpy and size, by changing temperature. CAD migration and CAD translation are also two of the technologies used today, to test the structure and engineering of the product as a whole.

These services help to some extent, prevent problems and waste time on product conversion after processing. It can be done in the design phase itself. Due to the importance and demand for mechanical services in many industries, the demand for machine designers is growing.

Equipment design assists designers in the following ways:

- Choosing the right items and the right conditions,

- Calculate the size according to the loads on the machines and the power of the story,

- Specify the manufacturing process for a partial design for the machine or the whole machine.

Machine engineering design involves the use of mathematics, kinematics, statics, dynamics, mechanics of materials, engineering materials, mechanical technology of metals, and engineering drawing. It includes the use of other topics such as thermodynamics, electrical theory, hydraulics, engines, turbines, pumps, etc. Machine drawing is an important part of machine design because all parts of machinery are designed to be drawn to make it according to specific definitions. Without machine design the title of the machine design is incomplete. Today’s organizations work tirelessly to deliver unique products to their customers in order to keep up with the ever-increasing competition. The delivery of large products requires smooth production and assembly construction so that each step of the process of adding value is much faster than before. Production and assembly incorporation of product design and process planning into one. The main purpose of the design of any product is to bring about something economically profitable with high quality. It is important to note that organizations may incur more than 75% of product costs during the completion of the design process while other production costs are estimated at the time of production decisions.

When launching a product, managers should ensure a reduction in product management during the suspension, direction, or adjustment of a particular part of the product. Equal parts should be used to avoid failure. Clear guidelines for component and product management should be provided to employees as it prepares the work culture and improves the integration process. Units should minimize damage to property and waste components during production and packaging. The assembly process for any production unit should be simple and flexible. Managers must ensure that the composition is guaranteed in its products and materials. Products should be designed to have a self-testing r test. Any handiwork without value addition should be minimized and the connection of processes. Any production process that uses the design of printed circuit boards should reduce partial variability, allow for standard packaging, and maintain normal material consistency.

Manufacturing and integration design is an important part of product development. Much of the time and effort is devoted to improving the structure of these processes as organizations that are well versed in these areas tend to maximize corporate profits. Once the company has decided to proceed with the product / artifact, the next step is to go to a technical engineering service provider. Since product design can have many responses, there is often an iteration involved in the design process. The construction services company will handle all of this rotating duplication. Here are the basic steps taken by any engineering construction service provider:

Identify project requirements

This process usually contains a list of product function and customer requirements and expectations regarding product features.

Collect relevant information about the product

More research goes into this step. It can include studying competitors’ products, reading books, browsing the internet about similar products and talking to potential buyers. This step also includes identifying the loads, parameters, conditions and strengths to be used in the product. Product design should be such that it helps to work smoothly for the purpose of the product under very difficult conditions. At the same time, construction needs to be improved and more attractive.

Think of possible solutions

Since design engineering is a mixture of science and art, there can be more than one solution for product development. The engineering construction services team discusses various options that can lead to an excellent artifact. It is also important to ensure that costs and development time are kept to a minimum. This requires finding the right product for the first time. Today’s state-of-the-art CAD software is accurate and suggestive. They also contain a standard library that can help designers meet the required standards and design goals. CAE software solutions enable the engineering construction service team to analyze and mimic product designs that highlight weaknesses in the construction that in turn help companies develop robust product designs.

Focus into the most common solution

After reviewing all “What if” scenarios, companies can streamline the design they wish to pursue.

Launch and test the building solution

The advent of 3 D Printers has made prototyping easier. Many engineering service delivery companies use a 3 D printer to create a 3 D object. The design of the visual model helps companies ensure product performance, balance, form and ergonomics. This further helps to improve the performance of the product design.

Engineering is always a process of improving the truth so all engineers – no matter what stage of their career – always feel that they have a lot to learn. During the design process, previously thought-out solutions go to the real world. Prototyping provides a great opportunity for engineers to learn from their mistakes without having to face the consequences. During the design phase of the design process, concepts are transformed into models used for testing. This is where real learning takes place because the whole group will be making notes about the testing and performance of the type of model mentioned in its desired location. It has never been a question of success or failure but of improvement.

Also Read: Will Mechanical Engineering Services Ever Rule The World?